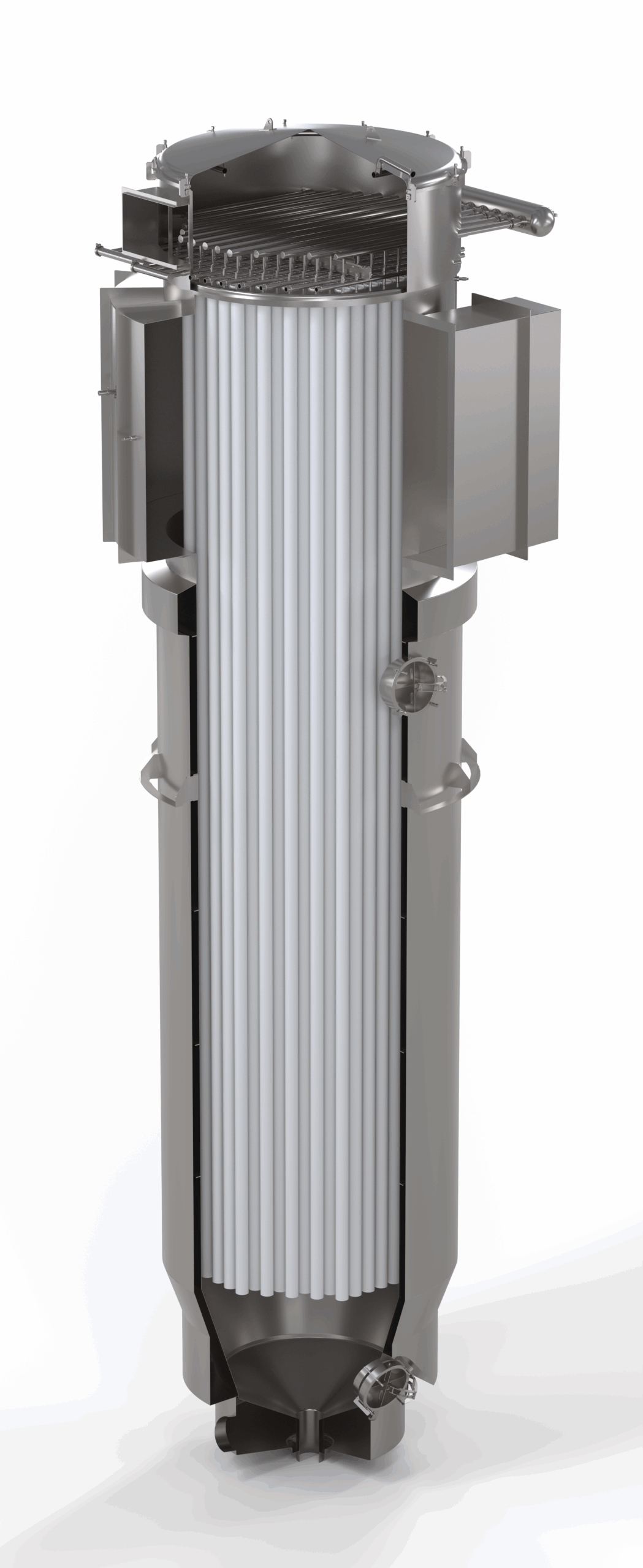

CIP Bag Filter

CIP Bag Filter – hygienic design for food and pharma production

The patent pending Filtersupport CIP Bag Filter integrates internal and external cleaning into a single CIP system.

It is developed for spray dryers and pneumatic conveying systems where hygiene and reliability are critical.

Design features:

- Sanitary clean-air chamber with polished welds and full drainability

- Zoned CIP coverage: both inside and outside of filter bags

- No disassembly required → safe and quick cleaning

- Materials and surface finish according to food & pharma standards

- Full documentation: material certificates, weld maps, validation protocols

- Dokumentation: materialecertifikater, svejserapporter, valideringsprotokoller

Sanitary CIP Filter – Designed for Food and Pharma

CIP-Cleanable Bag Filter – Hygienic Design for Demanding Applications

Filtersupport ApS offers a high-performance CIP (Cleaning In Place) -cleanable bag filter, engineered for use in hygienically sensitive industries such as food, dairy, pharmaceuticals, and biotech.

Constructed in stainless steel with food-contact compliant materials throughout, in accordance with EN 1672-2 Hygienic Design principles, the system ensures reliable operation, easy maintenance, and full in accordance with EU food contact regulations (1935/2004, 10/2011, 2023/2006).

Key Features:

- ✔ Fully CIP-cleanable – complete cleaning without disassembly

- ✔ Sanitary construction with fully welded joints and Ra ≤ 0.8 µm & Ra ≤ 0.3 µm internal surface finish in product contact areas

- ✔ Integrated spray nozzles – Integrated spray nozzles – for complete cleaning of filter chamber, tube sheet, and both the exterior and interior of the filter bags, including through the filter media

- ✔ Hygienic filter bag system with snap ring and food-grade materials

- ✔ Optional explosion protection and fire suppression in compliance with EN 14491 and VDI 2263 -7.1

- ✔ Designed for pressure shock resistance (e.g. 0.6 or 1.0 bar), in accordance with EN 14460

The system is ideal for installations where product safety, fast batch changeovers, and documented CIP performance are critical. Suitable for hygiene zones, and explosive dust environments.